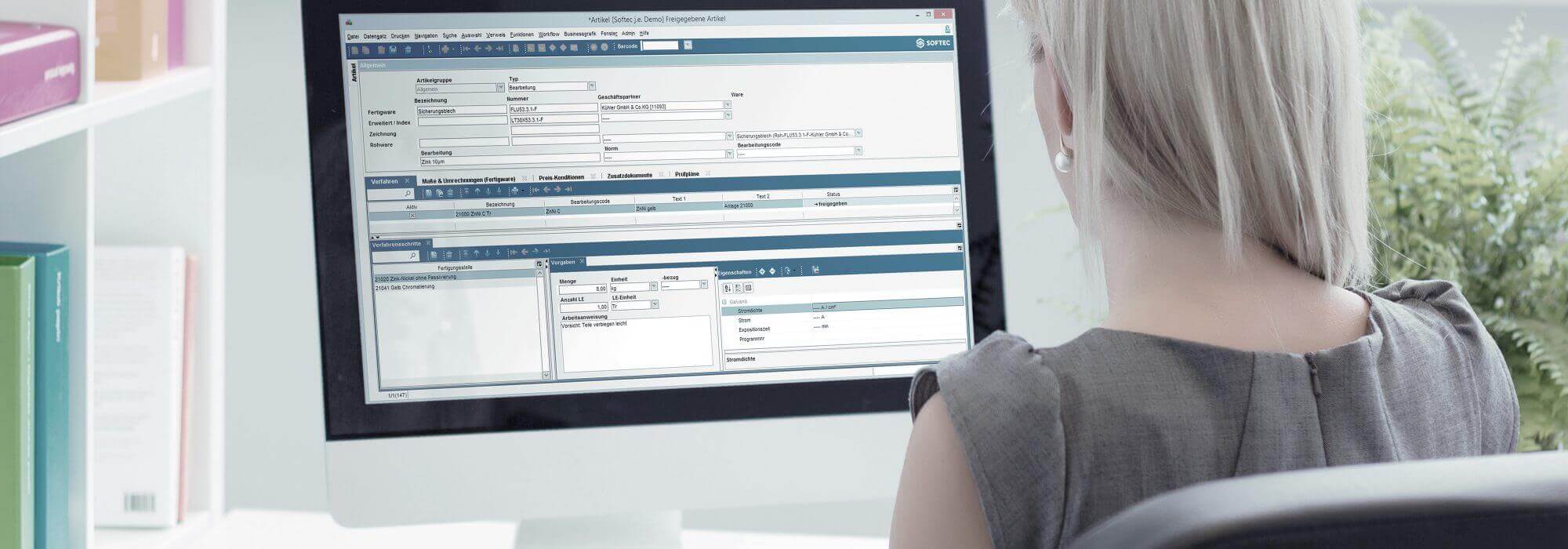

The leading ERP solution for surface finishing is designed as a modular concept which allows you to adapt the system according to your processes at any time:

OMNITEC

More than 180 customers from the industries electroplating, powder coating, anodising, painting, heat treatment and other sub-sectors rely on our software solution.

Your benefits

OMNITEC. Developed for the surface finishing industry.

Continuous

in one system from the shipping notification to the outgoing goods

AUTOMATED INDUSTRY WORKFLOWS

and mapping of industry-relevant standards and procedures

HIGHLY FLEXIBLE Proposal Generation

including precious metal management for electroplating and with deposited price group systems according to colours for powder & lacquer

INTEGRATED QUALITY CONTROL

for planning, controlling and documentation of your QC measures

INTEGRATED INVENTORY MANAGEMENT SYSTEM

including colour management and packaging material management

CONVENIENT MASTER DATA MANAGEMENT

for mapping even complex customer or supplier relationships

Highlights of OMNITEC V14

CENTRAL ACTION MONITORING:

Complaints, insufficient test results, standards management and maintenance of measuring equipment – merged in a brand new information center!

PACKAGING EFFICIENCY:

Complex outbound packaging regulations – Automatic proposals of complex outbound packaging directly at the packaging and delivery stage.

VDA to go:

Capture data wherever it occurs

AUTOMATION OF QA TESTS THROUGH MULTIPLE RANDOM SAMPLES

EXTENSIVE EXPANSION OF THE INVENTORY MANAGEMENT:

Discover numerous new convenience functions, such as retroactive accounting and cost splits for inventories!

MAINTENANCE:

Maintenance calendar as an overview of all measures – Plant management for monitoring and processing all target dates and measured values for baths and components – Automatic generation of payroll data derived from the capture of production data – Mobile recording of meter readings

Information Hotspots:

Promoting communication in the work process – personalized planning boards at key positions

AUTOMATIC CALCULATION OF COMPLAINT COSTS

OMNITEC modules:

Maximum flexibility in the design of your ERP system

OMNITEC ERP:

Get started with order management, costing and pricing, quotation management, materials management and invoicing.

OMNITEC QM:

Benefit from quality management proven in surface finishing and a complete quality history including all processes, instruments and data.

OMNITEC Handling UNIT Management:

Rely on packaging logistics that meet the special requirements of the automotive industry.

OMNITEC Planning:

Optimize your production planning with regard to lead times, system capacity, colour change, set-up times and consumption.

OMNITEC PDA:

Use the feedback of your production for the optimized control of your processes.

OMNITEC MAINTENANCE:

Ensure value retention and maximum system availability – with a module that supports you in the inspection, maintenance and repair of your plants.